Imagem 1 de 12

Imagem 1 de 12

Imagem 2 de 12

Imagem 2 de 12

Imagem 3 de 12

Imagem 3 de 12

Imagem 4 de 12

Imagem 4 de 12

Imagem 5 de 12

Imagem 5 de 12

Imagem 6 de 12

Imagem 6 de 12

Imagem 7 de 12

Imagem 7 de 12

Imagem 8 de 12

Imagem 8 de 12

Imagem 9 de 12

Imagem 9 de 12

Imagem 10 de 12

Imagem 10 de 12

Imagem 11 de 12

Imagem 11 de 12

Imagem 12 de 12

Imagem 12 de 12

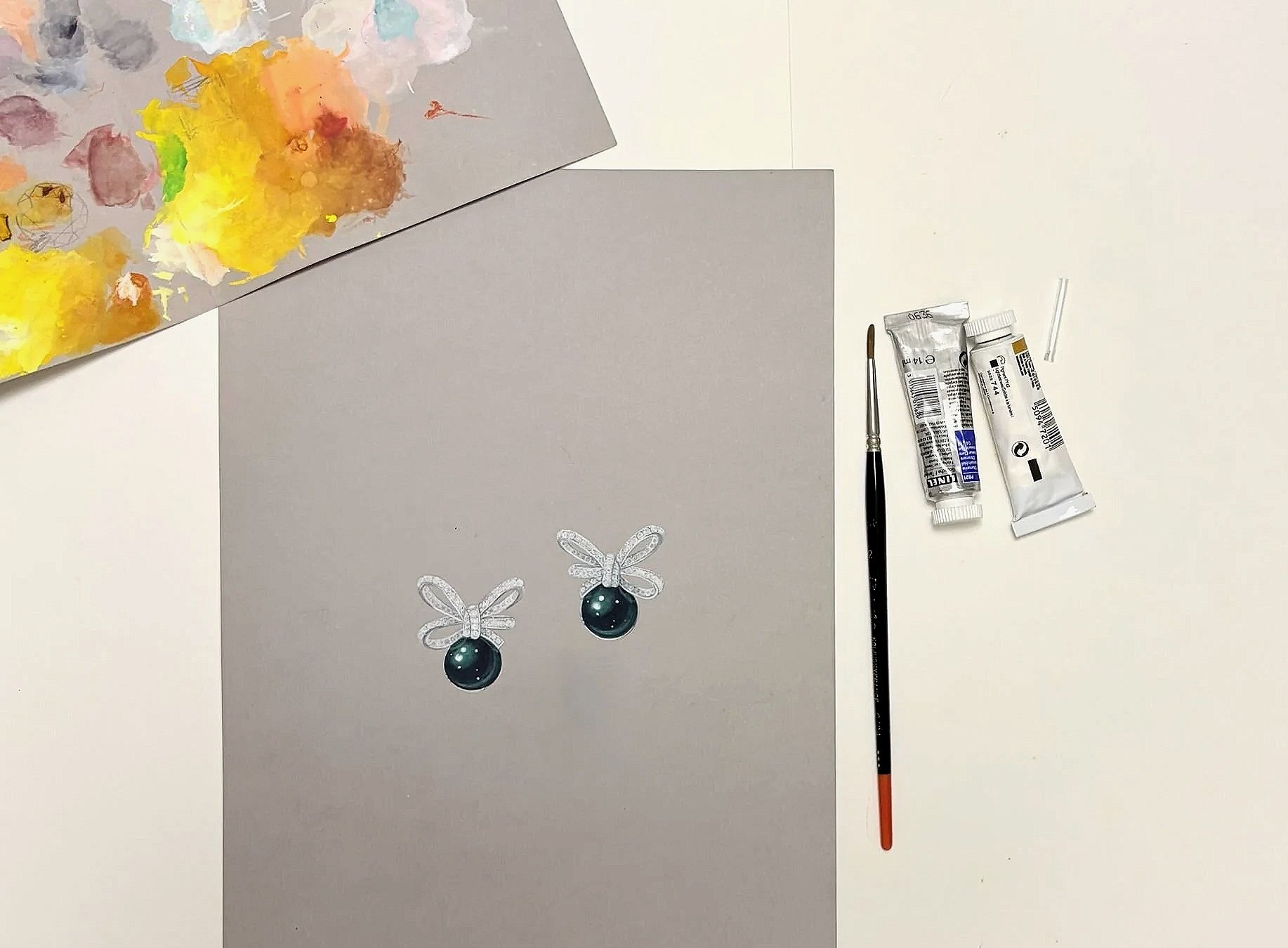

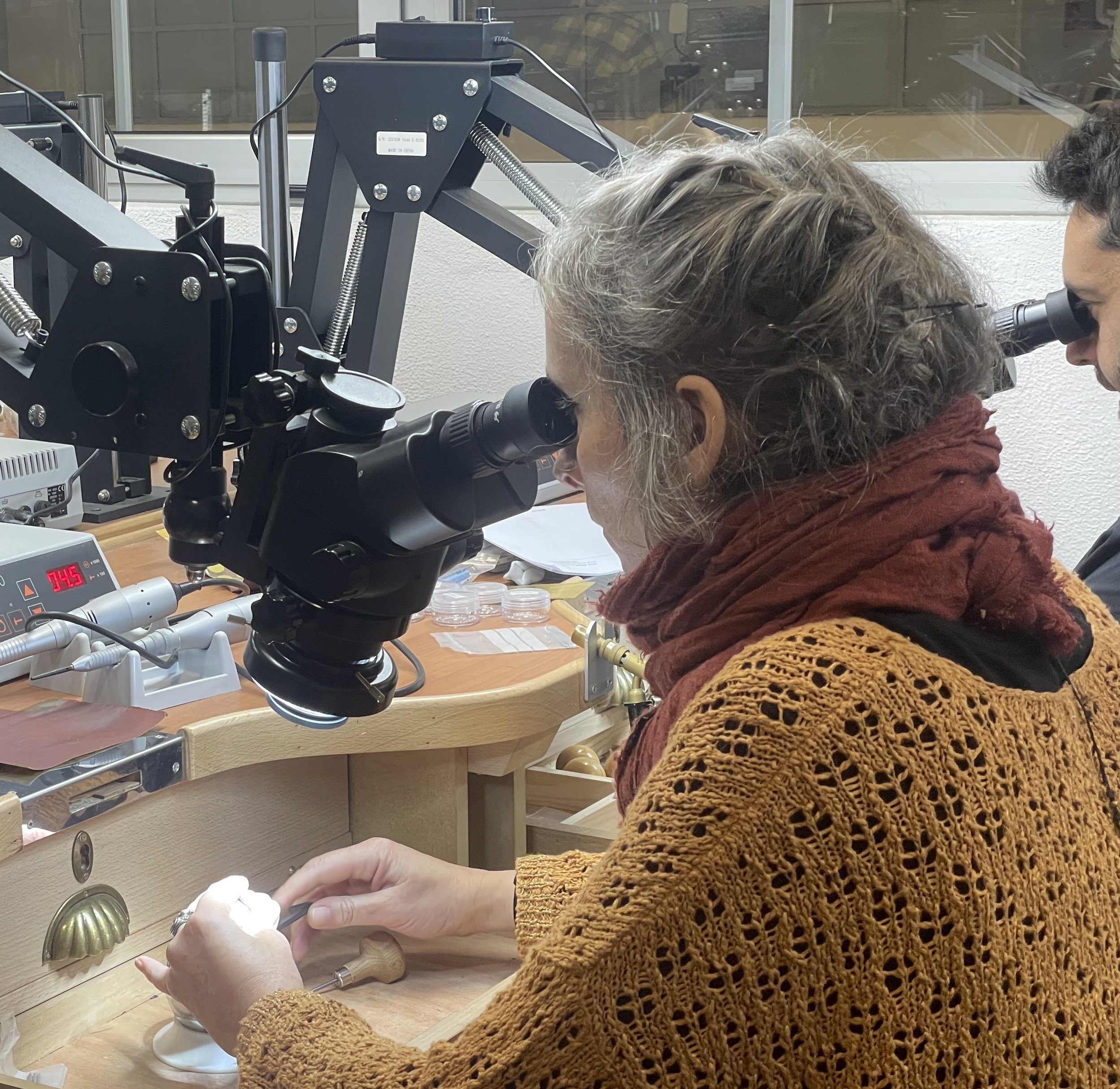

Micro stone-setting SPECIALISATION

SPECIALISATION (New program | Beginer + advanced levels)

90 hours (+FREE individual practice during the course)

April 11 to July 18 2026 / Saturdays 9:30-13:30 e 14:30-17:30

Limited to 6 places (mixed group PT + ENG)

________

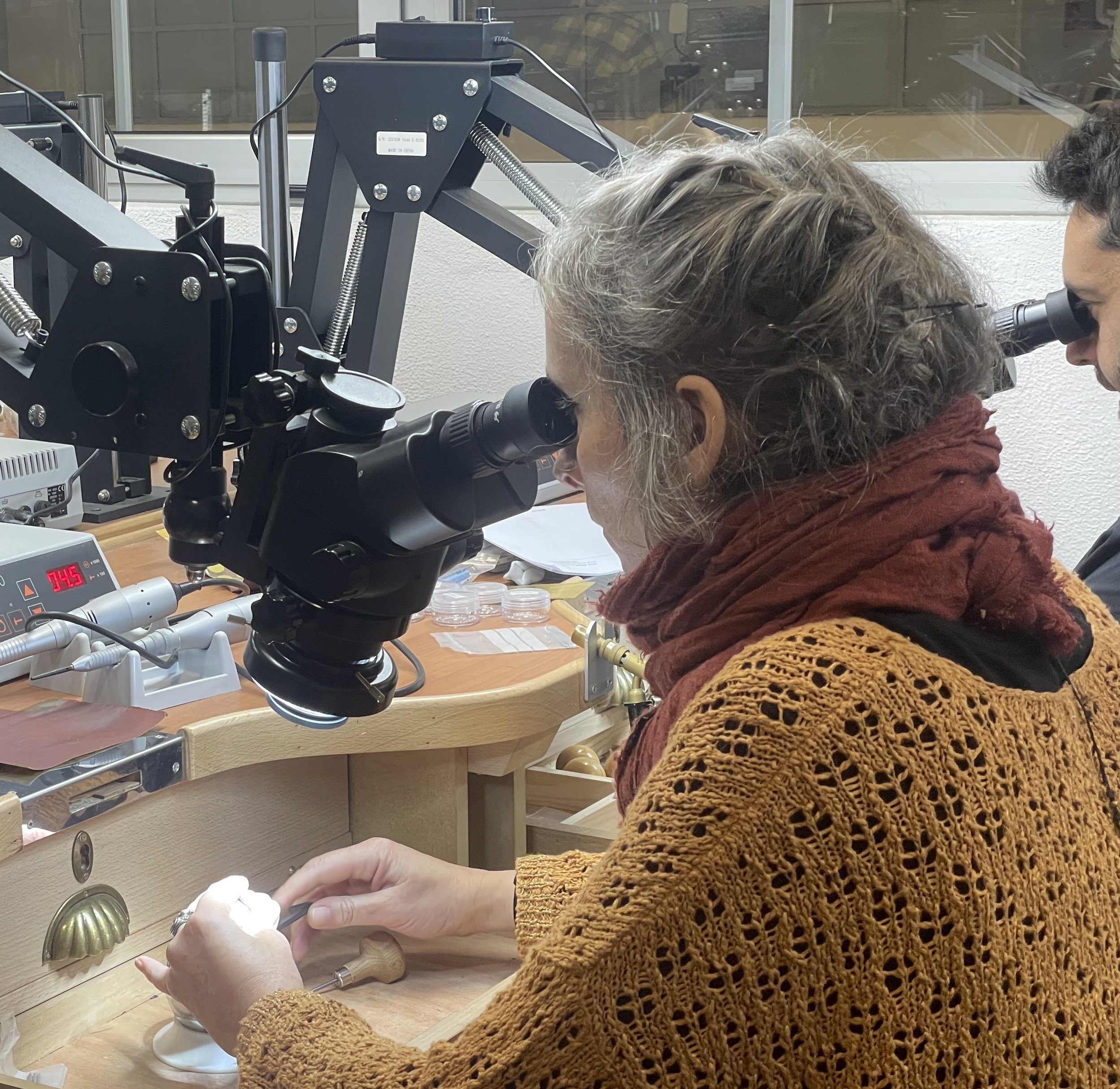

Under the guidance of highly specialised master stone setter André de Carvalho (with experience at Rosior, Chopard, De Grisogono, and Cartier), students will learn and develop through advanced practical exercises, the fundamentals of micro-setting techniques using a microscope, electric graver (NEW!) and vise ball to achieve precision work.

Explore advanced stone-setting methods that combine traditional expertise with modern technologies.

The methodology is based on individual practical exercises on plates and semi-finished jewellery pieces.

Monitoring and open discussion of each student's work take place via amplified video.

Our approach promotes precision and speed in execution.

The programme focuses on the main stone-setting techniques used in jewellery, with particular emphasis on pavé — a technique widely employed in high jewellery.

At the end of the course, the student will be able to plan and execute — autonomously and with high quality and precision — all the fundamental stone-setting techniques, using a microscope and an electric graver, including pavé settings, both on three-dimensional pieces (in volume) and on flat surfaces.

TARGET GROUP All interested parties, whether students or jewellery professionals, with experience in basic jewellery-making techniques: sawing, filing, sanding and drilling, who wish to specialise in stone-setting or complement/consolidate their knowledge.

CAREER OPPORTUNITIES

Freelance setter; Jewellery and watchmaking workshops and factories.

REQUIRMENTS:

Basic jewellery-making techniques: sawing, filing, sanding and drilling.

NUMBER OF STUDENTS PER GROUP: Minimum/Maximum 5/6

PROGRAM:

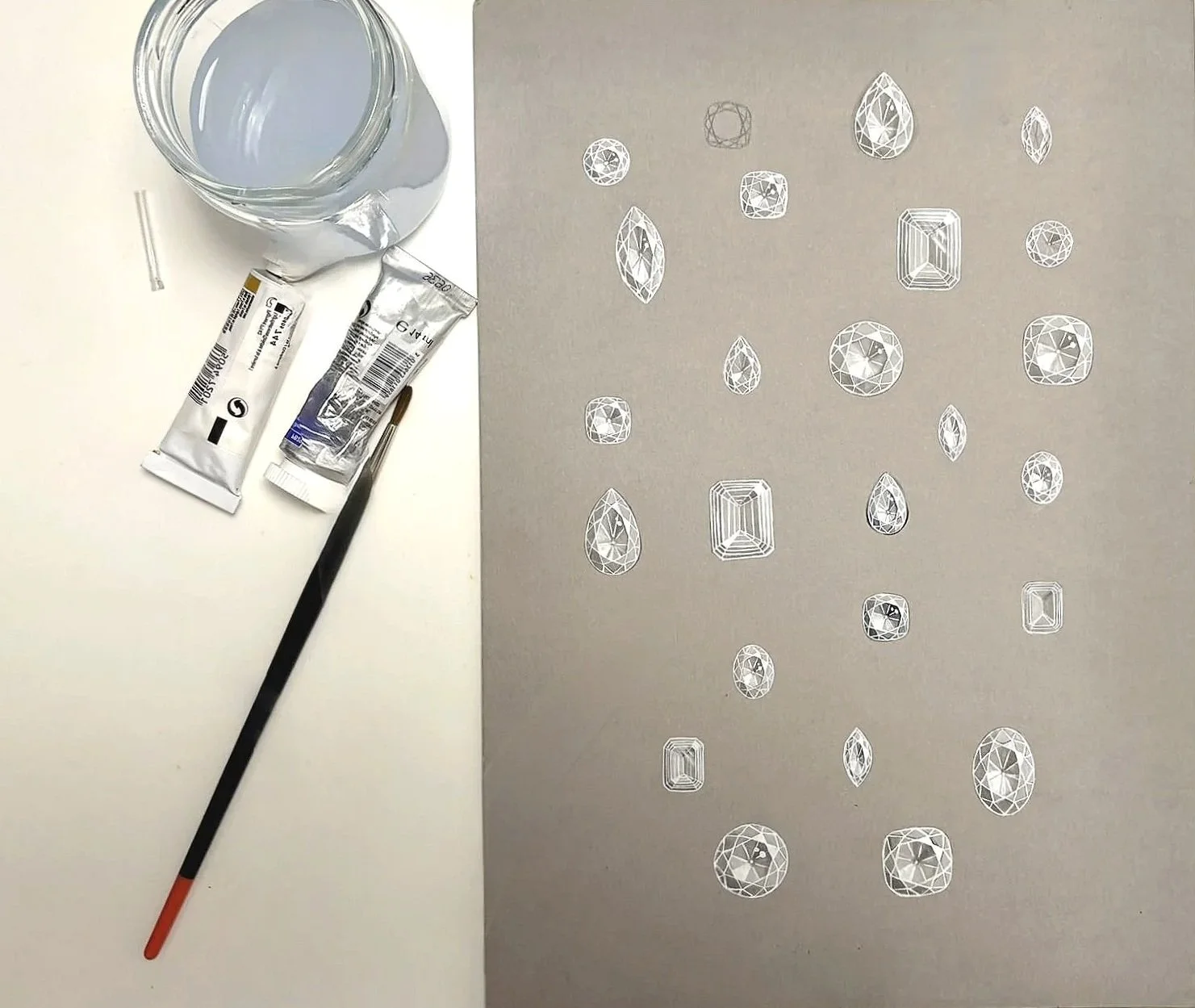

1 – Introduction, theory and workstation preparation

Physics of precious stones and metals in the context of stone setting;

Setup of equipment (microscope, electric graver, setting ball);

Ergonomics, lighting and workspace organisation;

Identification and preparation of tools.

2 – Control of the electric graver

Configuration of the electric graver for different cuts and depths;

Intensive practice on sheet metal: straight and curved cuts with appropriate gravers.

3 – Theory and practice of marking and drilling

Use of measuring and marking tools (calliper, ruler, dividers);

Spacing between holes;

Execution of drillings with ball burrs.

4 – Bezel setting and flush setting

Bezel setting with different types of stones (square, faceted and cabochon);

Flush setting of round stones.

5 – Prong setting

Prong setting of an oval stone with 4 prongs;

Prong setting of a round stone with 4 prongs;

Prong setting of a pear-shaped stone with 8 prongs.

6 – Channel setting

Channel setting with square stones (princess cut).

7 – Straight-line Pavé setting

Pavé setting in a flat surface (single row of round stones);

Pavé setting in volume/curved surface (single row on a ring shank).

8 – Castle setting

Castle setting on a ring – multiple stones.

9 – Zig-Zag Pavé setting with geometric pattern

Zig-zag pavé setting in a triangular/decreasing pattern on sheet metal.

10 – Zig-Zag Pavé setting on a ring

Zig-zag pavé setting with two rows, on a ring.

11 – Fishtail setting

Continuation and completion of the fishtail technique;

Fishtail setting on a ring with multiple stones.

12 – Final Project – Free organic Pavé theme piece design of the pattern;

Planning and combination of stones in varying sizes.

13 – Conclusion

Clarification of doubts;

Completion of unfinished projects and pieces;

Final finishing touches.

________

If you have questions call +351 213 929 673 or email catiafranco@cjlx.pt

All materials, consumables and stones are included in the price.

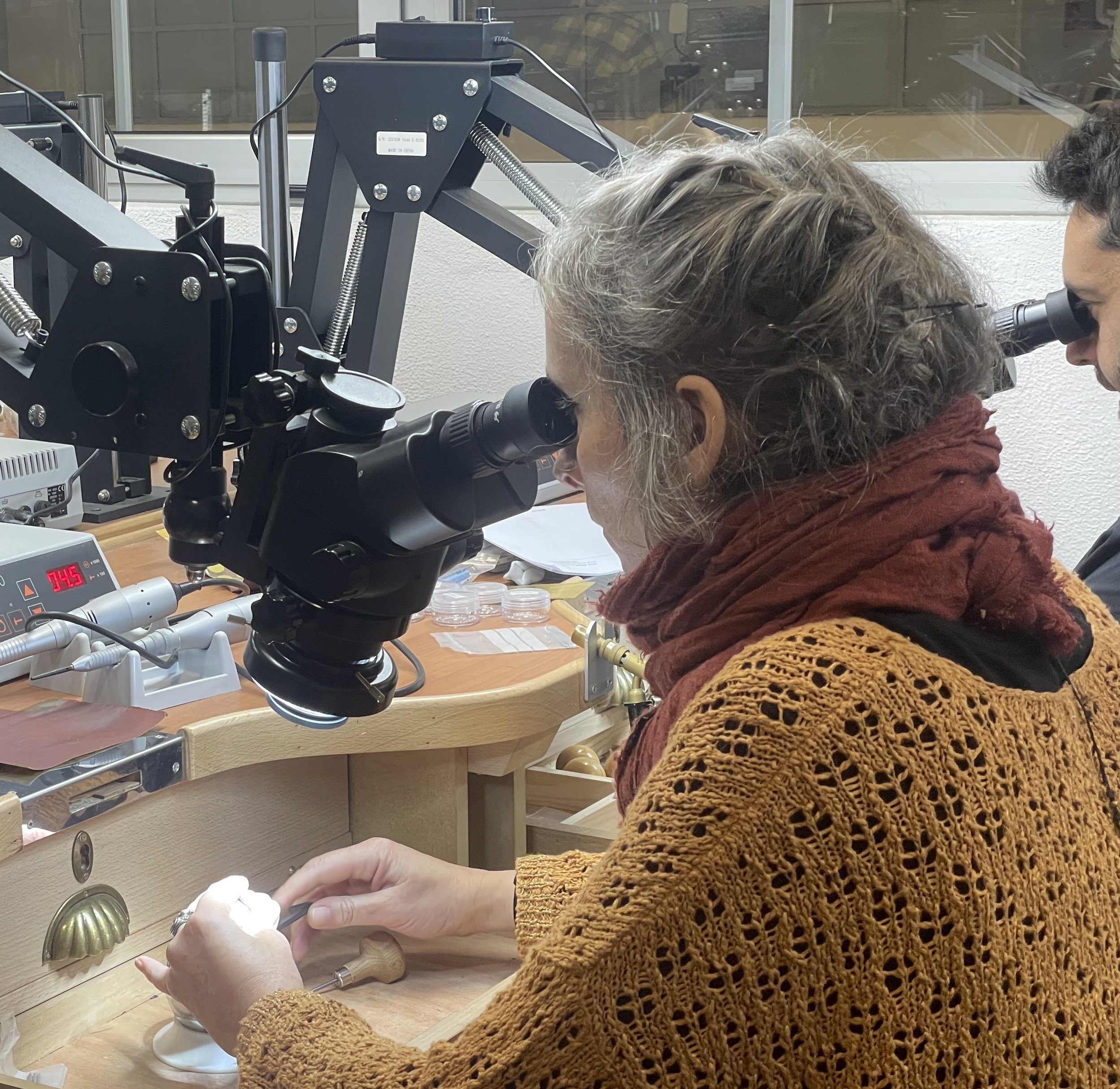

SPECIALISATION (New program | Beginer + advanced levels)

90 hours (+FREE individual practice during the course)

April 11 to July 18 2026 / Saturdays 9:30-13:30 e 14:30-17:30

Limited to 6 places (mixed group PT + ENG)

________

Under the guidance of highly specialised master stone setter André de Carvalho (with experience at Rosior, Chopard, De Grisogono, and Cartier), students will learn and develop through advanced practical exercises, the fundamentals of micro-setting techniques using a microscope, electric graver (NEW!) and vise ball to achieve precision work.

Explore advanced stone-setting methods that combine traditional expertise with modern technologies.

The methodology is based on individual practical exercises on plates and semi-finished jewellery pieces.

Monitoring and open discussion of each student's work take place via amplified video.

Our approach promotes precision and speed in execution.

The programme focuses on the main stone-setting techniques used in jewellery, with particular emphasis on pavé — a technique widely employed in high jewellery.

At the end of the course, the student will be able to plan and execute — autonomously and with high quality and precision — all the fundamental stone-setting techniques, using a microscope and an electric graver, including pavé settings, both on three-dimensional pieces (in volume) and on flat surfaces.

TARGET GROUP All interested parties, whether students or jewellery professionals, with experience in basic jewellery-making techniques: sawing, filing, sanding and drilling, who wish to specialise in stone-setting or complement/consolidate their knowledge.

CAREER OPPORTUNITIES

Freelance setter; Jewellery and watchmaking workshops and factories.

REQUIRMENTS:

Basic jewellery-making techniques: sawing, filing, sanding and drilling.

NUMBER OF STUDENTS PER GROUP: Minimum/Maximum 5/6

PROGRAM:

1 – Introduction, theory and workstation preparation

Physics of precious stones and metals in the context of stone setting;

Setup of equipment (microscope, electric graver, setting ball);

Ergonomics, lighting and workspace organisation;

Identification and preparation of tools.

2 – Control of the electric graver

Configuration of the electric graver for different cuts and depths;

Intensive practice on sheet metal: straight and curved cuts with appropriate gravers.

3 – Theory and practice of marking and drilling

Use of measuring and marking tools (calliper, ruler, dividers);

Spacing between holes;

Execution of drillings with ball burrs.

4 – Bezel setting and flush setting

Bezel setting with different types of stones (square, faceted and cabochon);

Flush setting of round stones.

5 – Prong setting

Prong setting of an oval stone with 4 prongs;

Prong setting of a round stone with 4 prongs;

Prong setting of a pear-shaped stone with 8 prongs.

6 – Channel setting

Channel setting with square stones (princess cut).

7 – Straight-line Pavé setting

Pavé setting in a flat surface (single row of round stones);

Pavé setting in volume/curved surface (single row on a ring shank).

8 – Castle setting

Castle setting on a ring – multiple stones.

9 – Zig-Zag Pavé setting with geometric pattern

Zig-zag pavé setting in a triangular/decreasing pattern on sheet metal.

10 – Zig-Zag Pavé setting on a ring

Zig-zag pavé setting with two rows, on a ring.

11 – Fishtail setting

Continuation and completion of the fishtail technique;

Fishtail setting on a ring with multiple stones.

12 – Final Project – Free organic Pavé theme piece design of the pattern;

Planning and combination of stones in varying sizes.

13 – Conclusion

Clarification of doubts;

Completion of unfinished projects and pieces;

Final finishing touches.

________

If you have questions call +351 213 929 673 or email catiafranco@cjlx.pt

All materials, consumables and stones are included in the price.